Global and Regional ABC Codes

Back to Global and Regional ABC Codes (feature table).

This topic provides information on the three-level ABC code structure implemented in Vision release 9.3.0 and above.

Overview

With release 9.3 and above, Vision provides three different levels of ABC ranking codes.

With the implementation of global and regional ABC codes, the codes retain the same meaning and behavior as before but now you can establish ABC codes for parts at three different levels:

|

Level

|

Range of Application

|

|

Warehouse

|

Individual warehouse.

|

|

Region

|

Two or more warehouses grouped together.

|

|

Global

|

All warehouses.

|

Each part can have a different ABC rank at each level. Thus, when purchasing a part for a specific warehouse, a group of warehouses, or for all warehouses, the purchase is affected by the ABC rank for that part at that level. For example, if Vision is configured properly, when a part needs to be replenished for your northwest region, the ABC ranking that is applied to the calculation can be specific to that region. Additionally, each warehouse within that region can have a different ABC model. In this way, you can take advantage of economies of scale that apply to a larger region while still maintaining the level of granularity needed for a specific warehouse. With three levels of ABC ranking, it’s possible to generate more economical purchase orders that can cost less while providing more value for each purchasing dollar.

Back to Top.

Summary of Changes

Prior to release 9.3, Vision provided one level of ABC codes with the option of grouping warehouses together. Vision now provides three (3) levels of ABC codes.

|

ABC Functionality

|

Release 9.2 and below

|

Release 9.3 and above

|

|

ABC Code Levels

|

one

|

three: Warehouse, Region, Global

|

|

Warehouse Classification

|

Yes

|

Yes

|

|

Regional Classification

|

Partial

|

Yes

|

|

Separate ABC codes for Regional Classification of Parts

|

No

|

Yes

|

|

Global Classification

|

No

|

Yes

|

|

Separate ABC codes for Global Classification of Parts

|

No

|

Yes

|

|

ABC Models

|

unchanged

|

unchanged

|

|

Pricing Models

|

ABC Code

|

• ABC code

• ABC Level

|

|

ROP Models

|

ABC Code

|

• ABC code

• ABC Level

|

Back to Top.

Initial Default Values

When your system is initially upgraded to release 9.3, some parameters are set to initial values as follows:

|

Parameter Level

|

Parameter Name

|

Parameter Location

|

Initial Value / Comment

|

|

Part

|

ABC Code

(aka: Warehouse ABC Code, Whse ABC Code)

|

Part Management —> Main

|

This is the standard ABC code from previous Vision releases. There is no need to change these values. Vision will update them as usual.

|

|

Part

|

Region ABC

(aka: Region ABC Code)

|

Part Management —> Main

|

Set to the same as the Warehouse ABC Code. Usually, there is no need to change these values. Vision will update them as part of the system processes.

|

|

Part

|

Global ABC

(aka Global ABC Code)

|

Part Management —> Main

|

The global ABC codes are initially set to “None.” If you have configured your system to use global ABC codes, Vision will update these codes as part of the system processes.

|

|

Warehouse

|

ABC Default Level

|

Vision Configuration —>

System Configuration —>

Warehouse —>

[Selected Warehouse] —>

ABC/ROP Options >

ABC Classification

|

If the “Additional Warehouses to Combine for Classification” check box list has warehouses checked, then the ABC Default Level is set to Region for that warehouse and for all the warehouses that are checked in the list. Otherwise the ABC Default Level will be set to Warehouse.

|

Back to Top.

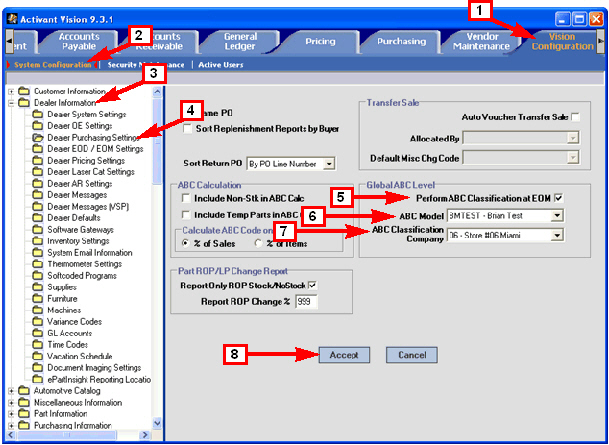

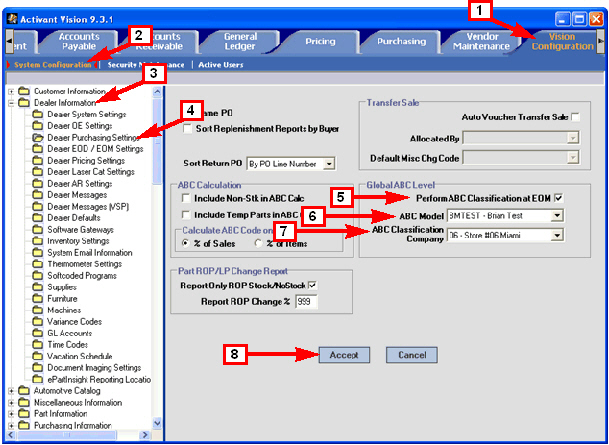

Specifying the Global ABC Level

|

Vision GUI Path

|

Vision Configuration —> System Configuration —> Dealer Information —>

Dealer Purchasing Settings > Global ABC Level : multiple parameters

Note: If any of the three fields in the Global ABC Level group is selected, then all three fields must be selected.

|

|

1 Click Vision Configuration.

2 Click System Configuration.

3 Open the Dealer Information folder.

4 Click Dealer Purchasing Settings.

5 Perform ABC Classification at EOM.

Check this box if you want ABC classification to be done during End Of Month processing. Checking this box causes the Global ABC code for parts to be updated.

6 ABC Model.

Select an ABC Model from the drop-down list. Vision will use this model when updating the Global ABC code for parts during ABC classification.

7 ABC Classification Company.

The system uses this company for determining the starting and ending general ledger periods to use if you elect to update the Global ABC code using the “Calendar YTD” or “Enter Date Range” options when running “ABC Classification based on ABC Model.” Please see page 38 for related information.

8 Click Accept to save your changes.

Back to Top.

|

|

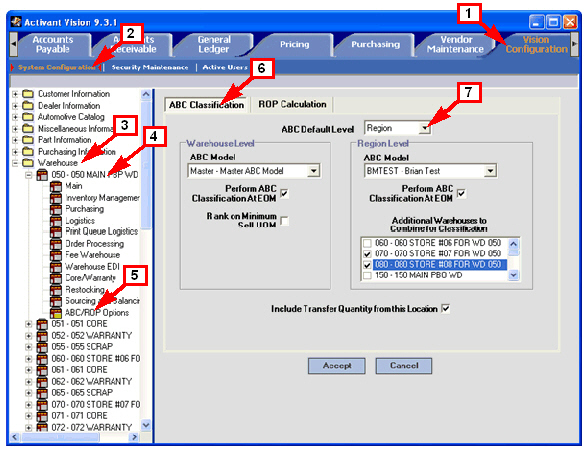

Specifying ABC Levels for the Warehouse and Region

|

Vision GUI Path

|

Vision Configuration —> System Configuration —> Warehouse —>

[Selected Warehouse] —> ABC/ROP Options > ABC Classification > multiple parameters

|

|

1 Click Vision Configuration.

2 Click System Configuration.

3 Open the Warehouse folder.

4 Open the warehouse you want to edit.

5 Open the ABC/ROP Options screen.

6 Click the ABC Classification sub-tab.

7 ABC Default Level.

This drop-down list specifies the default ABC level for this warehouse. This level is used in processes and reports that do not allow you to specify the ABC code level. The possible values are as follows:

• Warehouse.

This is the default setting unless the warehouse is combined with other warehouses for classification.

• Region.

To use this setting, the warehouse must be part of an ABC classification grouping. It must either have one or more warehouses checked in the Additional Warehouses to Combine for Classification list or it must be selected in that list for another warehouse. If neither condition is true, then the system displays an error when you click Accept.

• Global.

To use this setting, a global ABC model must be selected under Dealer Information —> Dealer Purchasing Settings.

See Specifying the Global ABC Level for more information.

|

Note: See also Initial Default Values for more information about ABC Default Level.

|

|

Warehouse Level group box

8 ABC Model.

Select an ABC Model from the drop-down list. Vision will use this model during ABC classification for this warehouse.

9 Perform ABC Classification at EOM.

Check this box if you want ABC classification to be done during End Of Month processing. This causes the Warehouse ABC code for parts to be updated.

10 Rank on Minimum Sell UOM..

Check this box if you want to rank your products on the minimum sell unit of measure instead of the lowest unit of measure.

Region Level group box

11 ABC Model.

Select an ABC Model from the drop-down list. Vision will use this model during ABC classification for this warehouse if it is part of a regional group of two or more warehouses.

12 Perform ABC Classification at EOM.

Check this box if you want ABC classification to be done during End Of Month processing. This causes the Region ABC code for parts to be updated.

13 Additional Warehouses to Combine for Classification.

Check one or more warehouses to create a regional grouping of warehouses.

|

14 Include Transfer Quantity from this Location.

Checking this box, includes transfer quantities from this warehouse in the ABC classification. This check box applies to ABC Classification for the Warehouse Level, the Region Level, and also the Global level.

15 Click Accept to save your changes.

|

Back to Specifying ABC Levels for the Warehouse and Region.

Back to Top.

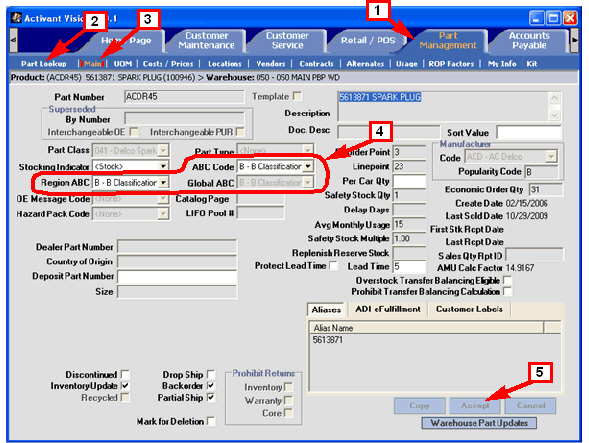

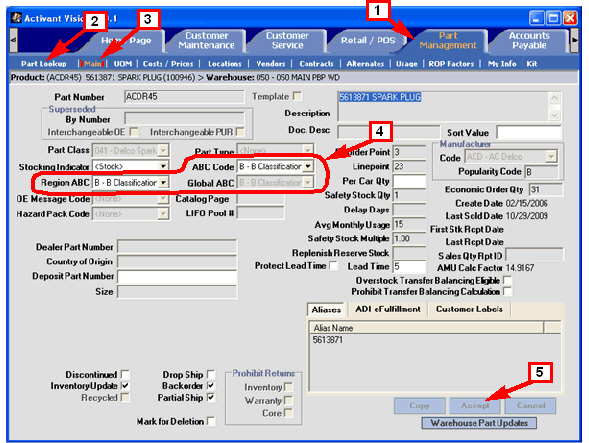

Configuring ABC Codes at the Part Level

Back to Top.

Part Management —> Main

|

1 Click Part Management.

2 Select a part using Part Lookup.

3 Click Main.

Depending on whether you performed a warehouse or global part lookup, different ABC code fields will be available:

• ABC Code

• Region ABC

OR

• Global ABC

4 Set the ABC codes you want.

5 Click Accept to save your changes.

Back to Configuring ABC Codes at the Part Level.

Back to Top.

|

|

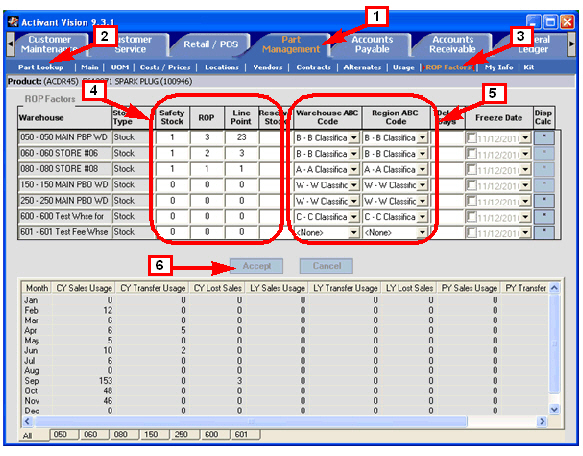

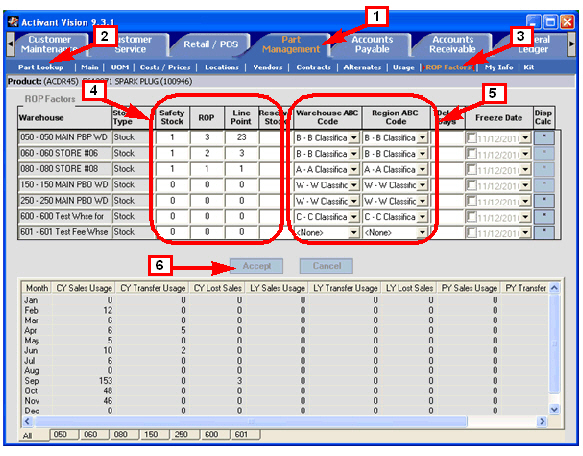

Part Management —> ROP Factors

|

1 Click Part Management.

2 Select a part using Part Lookup.

3 Click ROP Factors.

4 Make any desired changes.

5 Set the ABC codes as desired for this part.

Note: ABC Code is now named

Warehouse ABC Code and there is a new Region ABC Code.

6 Click Accept to save your changes.

Note: The Purchasing —> ROP Factors screen has changed in the same way as this screen.

Back to Configuring ABC Codes at the Part Level.

Back to Top.

|

|

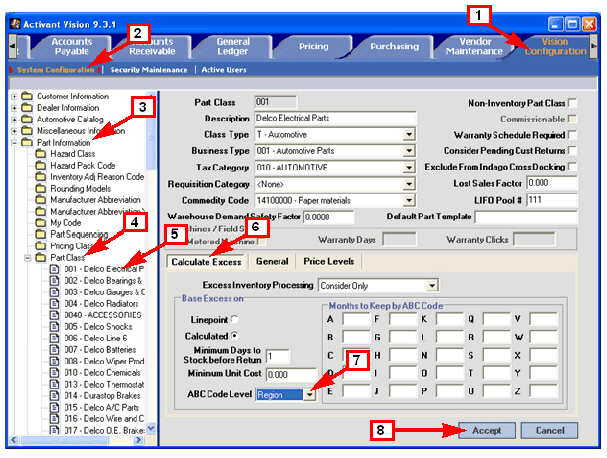

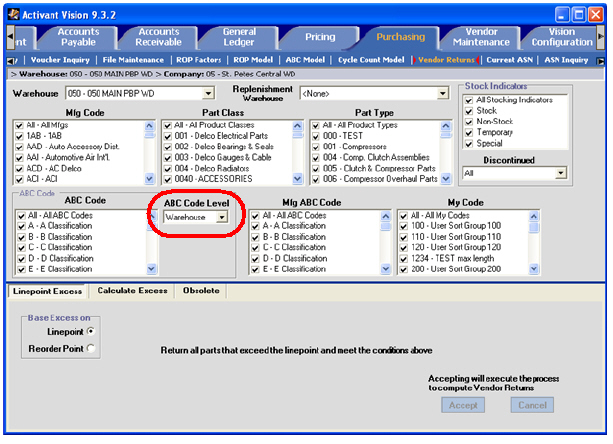

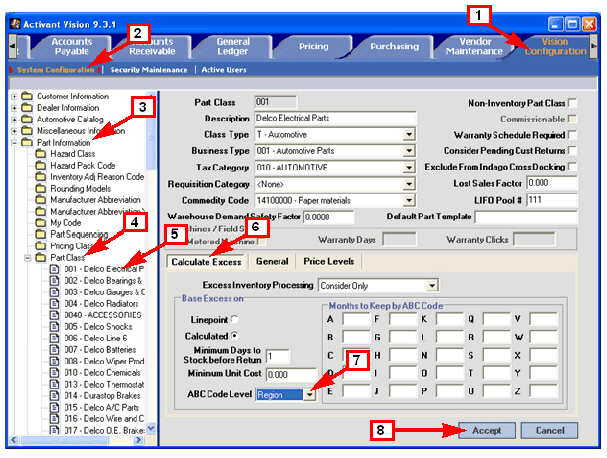

Calculate Excess

|

Vision Configuration —>

System Configuration —>

Part Information —>

Part Class —> [Selected Class] >

Calculate Excess

1 Click Vision Configuration.

2 Click System Configuration.

3 Click Part Information.

4 Click Part Class.

5 Click the desired part class.

6 Click Calculate Excess, if it is not already selected.

7 Set the ABC Code Level for this Part Class.

Choose from the following:

• Warehouse.

• Region.

• Global.

8 Click Accept to save your changes.

Back to Configuring ABC Codes at the Part Level.

Back to Top.

|

|

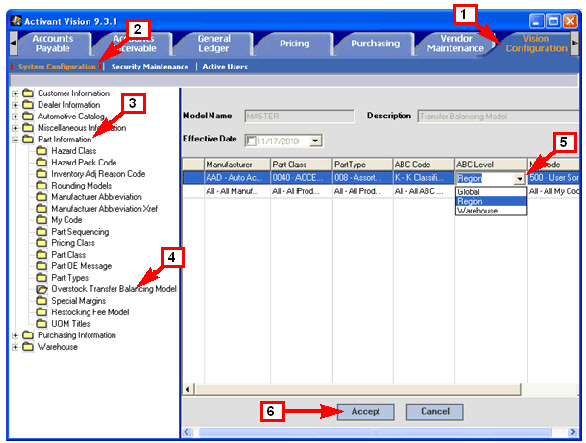

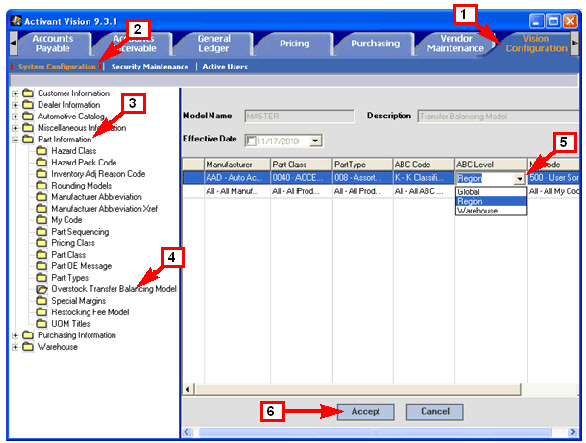

Overstock Transfer Balancing Model

|

Vision Configuration —>

System Configuration —>

Part Information —>

Overstock Transfer Balancing Model

1 Click Vision Configuration.

2 Click System Configuration.

3 Click Part Information.

4 Open the Overstock Transfer Balancing Model folder.

5 Set the ABC Level for each rule.

Choose from the following:

• Warehouse.

• Region.

• Global.

6 Click Accept to save your changes.

Back to Configuring ABC Codes at the Part Level.

Back to Top.

|

|

Configuring Purchasing With ABC Code Levels

Back to Top.

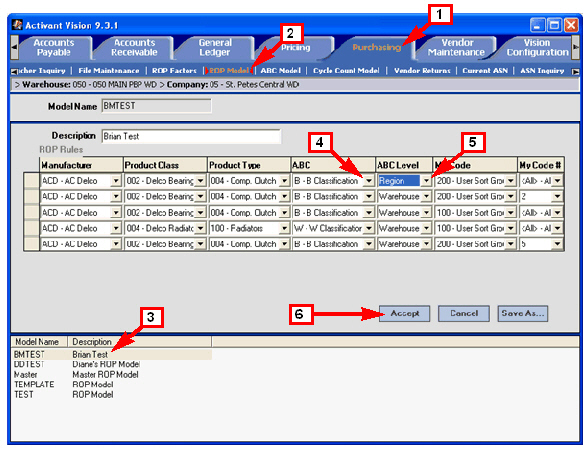

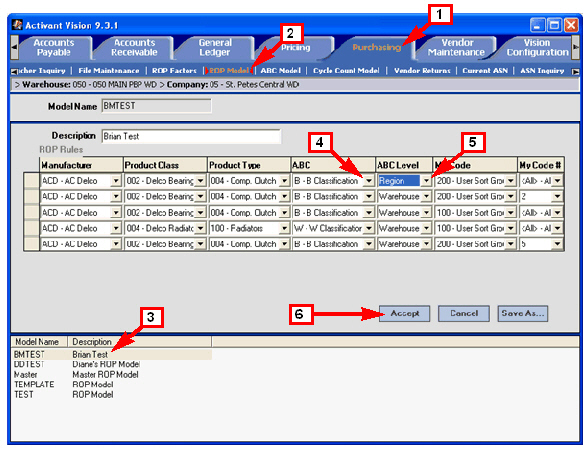

Purchasing —> ROP Model

|

Purchasing —> ROP Model —>

[Selected Model] :

• ABC

• ABC Level

1 Click Purchasing.

2 Click ROP Model.

3 Select the ROP model you want to edit.

4 Set the ABC code for each rule as needed.

5 Set the ABC Level for each rule.

Choose from the following:

• Warehouse.

• Region.

• Global.

6 Click Accept to save your changes.

Back to Configuring Purchasing With ABC Code Levels.

Back to Top.

|

|

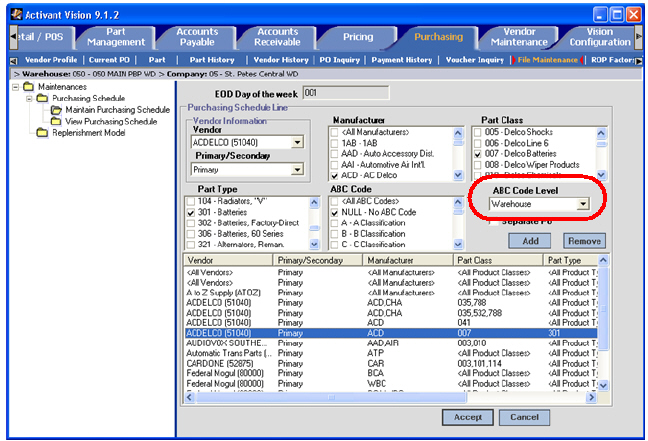

Maintain Purchasing Schedule

|

For every purchasing schedule rule, you must specify the ABC Code Level.

Choose from the following:

• Warehouse.

• Region.

• Global.

Note: For complete instructions on how to create purchasing schedule rules, please see the following topic in the online help:

Purchasing Schedules

Back to Configuring Purchasing With ABC Code Levels.

Back to Top.

|

|

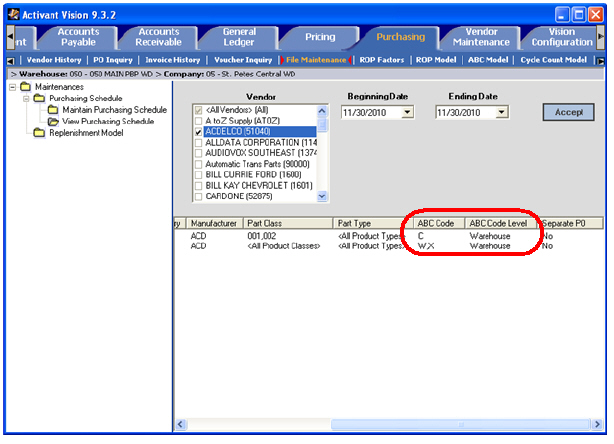

View Purchasing Schedules

|

When you view purchasing schedule rules, the system displays the following columns at the far right in the list view:

• ABC Code

• ABC Code Level

Note: For complete instructions on how to create and view purchasing schedule rules, please see the following topic in the online help:

Purchasing Schedules

Back to Configuring Purchasing With ABC Code Levels.

Back to Top.

|

|

Purchasing —> Vendor Returns

Configuring Price Models with ABC Levels

|

Vision GUI Path

|

Pricing —> Pricing Model —> [Selected Pricing Model] :

ABC Code, ABC Level

|

|

When you set up pricing models, you must specify the ABC Code Level.

Choose from the following:

• Warehouse.

• Region.

• Global.

Back to Top.

|

|

Back Office Functions

This section describes changes to Vision Back Office functions where you can explicitly specify the ABC Code Level (Warehouse, Region, Global) to apply to the process.

Stock Replenishment On Demand

Auto Menu 2.6.1

OP Menu 7.14.1

If you select a specific set of ABC codes (not ALL), then Vision displays an additional prompt:

(W)hse, (R)egion, or (G)lobal ABC Level:

You can enter either W, R, or G to specify which ABC level to use.

For example, if you specified C, D, and G as the ABC codes and you specified R for the level, then the system would only evaluate parts that have C, D, or G codes at the Regional level.

See these topics for related information:

• Configuring ABC Codes at the Part Level

• Purchasing —> ROP Model

Back to Back Office Functions.

Back to Top.

Pricing Calculation

Auto Menu 2.11.1

Pricing rules now include the ABC Code Level setting. The system selects only those parts that match the ABC Code and ABC Code Level as specified in each pricing rule in the price model. The system updates (or recalculates) the prices for only those parts.

See Configuring Price Models with ABC Levels for information on setting the ABC Code Level for pricing models.

Telepricing Updates and Other Processes

Telepricing updates and other processes that use price models also take into account the new ABC Code level field as part of the selection criteria for each Pricing rule.

Back to Back Office Functions.

Back to Top.

ROP and Average Monthly Usage Calculation

Auto Menu 2.17.4 — ROP and Average Monthly Usage Calculation

OP Menu 7.13.4 — Gordon Graham ROP/EOQ Recalculation

The ROP and Average Monthly Usage Calculation you run on demand and the ROP calculations that run during End of Month processing all use the ABC Code level you specify in the ROP model.

See Purchasing —> ROP Model for more information.

Back to Back Office Functions.

Back to Top.

ABC Classification based on ABC Model

Auto Menu 2.17.5

OP Menu 7.13.5

Vision displays a new prompt that lets you select the ABC Code level:

Calculate (W)hse, (R)egion, or (G)lobal ABC Level:

If you enter W or R, the Vision prompts for a warehouse. If you enter G, Vision does not prompt for a warehouse.

The system updates only those ABC codes that match the ABC code level you selected.

If you select an ABC code level that matches the ABC Default Level for the warehouse, then the classification process also updates the reorder delay days and the safety stock multiple fields. If the ABC code level you select does not match the ABC Default Level for the warehouse, the system does not update those fields.

See Specifying ABC Levels for the Warehouse and Region (step 7) for information about setting the ABC Default Level for the warehouse.

Back to Back Office Functions.

Back to Top.

Warehouse ABC Code Update

Auto Menu 2.17.6

Vision displays a new prompt that lets you specify which ABC Code Level to copy from the specified warehouse to the other warehouses:

Whse ABC Code, Region ABC Code, or Both (W/R/B):

Note: The Global ABC code already applies to all warehouses, so there is no need for a global option on this prompt.

Back to Back Office Functions.

Back to Top.

Product Upload

Auto Menu 11.3 — Product Upload (from Excel)

OP Menu 21.1.8 — Product Update (from Tab-delimited Excel spreadsheet)

You can set the Region ABC Code and the Global ABC Code fields when you upload product data from a spreadsheet. The new template has these two new fields added at the end.

|

Excel Column

|

CF

|

CG

|

|

Column Name

|

Region ABC Code

|

Global ABC Code

|

|

Column Number

|

84

|

85

|

|

Comment

|

only load if not null

|

only load if not null

|

You can download a blank copy of the spreadsheet template with these new fields here:

Product Upload Template

Note: There is also a link from the Welcome page of the Vision online help.

Back to Back Office Functions.

Back to Top.

EOM ABC Classification

If an ABC model is set for a warehouse, for a region, or globally at the dealer level, and “Perform ABC Classification at EOM” is set (checked) for that warehouse, region, or dealer, then the system runs ABC classification for that ABC Code Level.

See the following for additional information:

• Specifying the Global ABC Level.

• Specifying ABC Levels for the Warehouse and Region.

Back to Back Office Functions.

Back to Top.

EOD Purchase Order Generation

Vision purchasing rules have a new field: ABC Code Level. You can set this field differently for each purchasing rule. This field is included in the selection criteria for determining which parts to evaluate for inclusion on a purchase order.

See the following for additional information:

• Maintain Purchasing Schedule.

Back to Back Office Functions.

Back to Top.

Processes Using the ABC Default Level

Each warehouse has a setting called ABC Default Level. The system uses this setting in processes and reports that do not allow you to specify the ABC code level.

Note: See Specifying ABC Levels for the Warehouse and Region (step 7) for information about setting the ABC Default Level for the warehouse.

The system uses the ABC Default Level to determine which ABC codes to use during these processes:

• Selecting parts for Cycle Counting.

• Determining whether a returned part requires a Restocking Fee.

• Determining which ABC code to print on orders, invoices, and picklists when the “Print ABC Code” fields are checked.

(Vision Configuration —> System Configuration —> Warehouse —> Inventory Management > Print ABC Code)

• Reports where ABC Code is used as a selection criteria or sort method or is printed on the report. The individual reports are listed below.

|

Internal Report Name

|

Back Office Menu and Screen Title

|

|

PFUTURE.PRICING-RPT

|

M2.11.15 - Future Pricing Analysis Report

|

|

PINVENTORY.ANALYSIS-RPT

|

M3.2.8 - Inventory Analysis

|

|

PINVENTORY.HIST-RPT

|

M2.16.2.6 - Inventory History Report

|

|

PINVENTORY.SALES.WHSE-RPT

|

M3.2.15.5 - Warehouse Inventory Sales Report

|

|

PMANUAL.ROP-RPT

|

M2.17.2 - Items "M"anually Maintained for ROP Report

|

|

PNET.PROFIT-RPT

|

M10.1.7 - Net Gross Profit Report

|

|

PNONSTOCK.STAT-RPT

|

M10.1.2 - Non-Stock Status

|

|

PNONSTOCK.STAT.ON.HAND-RPT

|

M10.1.3 - Non-Stock Status with On-Hand > "0"

|

|

POBSOLETE.INV-RPT

|

M2.7 - Obsolete Invnty Report and Transfer Generator

|

|

PPARTS.NOT.UPD-RPT

|

run after spreadsheet load

|

|

PPROD.REPLEN.XREF.UPD

|

M2.6.4 - Update PROD_REPLEN_XREF Activity File

|

|

PPURCHASED.OIL-RPT

|

M10.18 - Oil Purchased/Sold Report

|

|

PSALES.12MO-RPT

|

M7.1.1 - 12-Month Sales History

|

|

PSTOCK.STAT-RPT

|

M10.1.1 - Stock Status

|

|

PSTOCK.STAT.INTERCHNG-RPT

|

M10.1.6 - Stock Status by Vendor or Mfg Abbr

|

|

PSTOCK.STAT.ON.HAND-RPT

|

M2.8.1 - Stock Status With On Hand > "0"

|

|

PSTOCK.STAT.ROP-RPT

|

not on menus anywhere, run by EX from ECL

|

|

PWHSE.LOC.RANK.EXCEPTIONS

|

M3.2.9 - Warehouse Location Ranking Exceptions

|

|

CUST.REPORT.CARD-RPT

|

M7.14.8.5 - Customer Report Card Report

|

|

DAILY.RECORD.CUST-RPT

|

OP M7.6.1.1.2 - Replenishment Action Report -- Customer Owned Only

|

|

DAILY.REORD-RPT

|

M 2.16.1.1 - Replenishment Action Report

|

|

EARN.TURN-RPT

|

M3.2.13 - Turn and Earn

|

|

SUGG.PENDING.PO-RPT

|

M2.16.1.8 - Suggested Pending PO Report

|

Back to Back Office Functions.

Back to Top.

Processes Exporting Vision Data to Other Systems

Some processes that export Vision data also use the ABC Default Level.

Note: See Specifying ABC Levels for the Warehouse and Region (step 7) for information about setting the ABC Default Level for the warehouse.

The system uses the ABC Default Level to determine which ABC codes to use during these processes:

• ePartInsight

• PartSource

• Quarterback

Compass

For Compass extracts, Vision sends all three ABC code levels (Warehouse, Region, and Global).

Back to Back Office Functions.

Back to Top.