Setting up ROP Factors

During EOD processing and on-demand stock replenishment, the system uses reorder point (ROP) models to calculate how much of a product to reorder. But if a product is new, or hasn't generated very many orders for a certain warehouse, there might not be enough usage data for the ROP model to be accurate.

If a product doesn't have enough usage data, you can use the ROP Factors screen to set ROP quantities manually and set freeze dates for the system to use the ROP quantities. The system checks for a freeze date before calculating ROP factors. If a freeze date is set in the future, the system uses the quantities you set on the ROP Factors screen. If there is no freeze date, or if the freeze date is in the past, the system uses the ROP model set in Vision Configuration. By the time the freeze date is past, the product should have enough usage data to calculate reordering amounts accurately.

If you didn't use manual ROP settings and freeze dates, you would have to set the ABC code to Manual, and then enter part information manually on the Main screen on the Part Management tab. Then you would have to remember to reset the ABC code once there is enough usage data.

You can view usage information at the bottom of the ROP Factors screen.

-

Note: You can change the ROP factors for a warehouse product only if the warehouse has an inventory class of sellable inventory, and if the product is stock or temporary. You usually will not need to modify a temporary product's ROP factors. For more information, see Specify the type of inventory that a warehouse carries.

Both the Purchasing tab and the Product Management tab have an ROP Factors screen. For instructions on using the ROP Factors screen on the Purchasing tab, refer to Set up or modify ROP factors for a product.

Setting ROP Factors Manually

To set ROP factors manually, do the following:

-

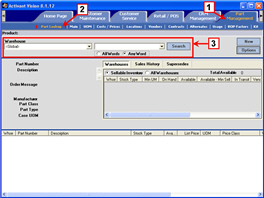

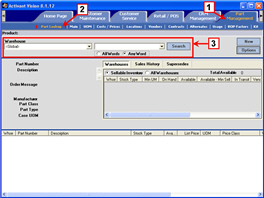

Click the Part Management tab.

-

Click Part Lookup.

-

Select a part.

Click here to see how to look up a part.

|

Click the image to see a larger view.

|

-

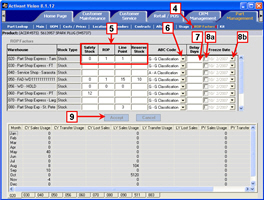

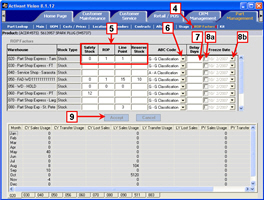

Click ROP Factors.

-

For each warehouse, type the

quantities used for ROP calculations.

If you leave any quantity blank, the system uses the standard ROP calculation. If you set a freeze date, you must set at least one of these quantities.

-

Select the ABC code.

-

Set the number of delay days, if needed.

The system waits to reorder the part for the number of days you set. If the customer returns the part during the delay period, then you won't have to reorder the part. Use delay days for slow-moving parts.

-

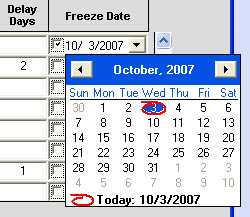

Set the freeze date.

-

Set the check box.

-

Select a future date from the

calendar.

The freeze date is the last date that the system will use the manual ROP quantities.

-

Click Accept.

|

Click the image to see a larger view.

|

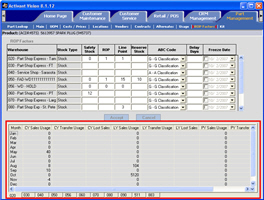

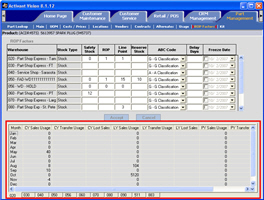

Viewing Usage Information

You can view usage information on the ROP Factors screen on the Part Management tab. Previously you could view this information only on the Usage screen.

|

Product Management --> ROP Factors

|

Click the image to see a larger view.

|