Consignment

/ Dealer Inventory

Back to Consignment / Dealer Inventory (feature

table).

These are the paths you will use to implement

Consignment/Dealer Inventory.

Vision

GUI Path |

|

|

|

|

Vendor

Maintenance —>Master > Status : Consignment Vendor

Customer Maintenance —> Ship

To Preferences > PO Requirements : Consignment Vendor

Vision Configuration —> System

Configuration —> Dealer Information —> GL Accounts : Consignment

Inventory.

Vision Configuration —> System

Configuration —> Dealer Information —>Variance Codes : Consignment

Inventory

Vision Configuration —> System

Configuration —> Dealer Information —> Dealer Defaults

> Consignment Inventory : GL Variance Code

Select the “Consignment Inventory”

variance code.

Customer Maintenance —> Consignment/Dealer

Inv

Purchasing —> Current PO

Customer Service —> Current Order

Customer Service —> Part (F5) |

Vision Back Office

Menu Path |

|

|

Auto |

3.9.1 |

Inventory Report |

|

|

|

3.9.2 |

Inventory Count Sheet |

|

|

OP |

8.9.1 |

Inventory Report |

|

|

|

8.9.2 |

Count

Sheet. |

|

Links to Main Topics in this Discussion

Overview

Consignment Inventory is inventory that you own

but which you have shipped to be stored at your customer’s facility (either

a store or a warehouse). You bill your customer for the inventory only

after it is sold. Essentially, the Consignment Inventory feature lets

your customer sell directly from your stock.

Vision provides the means for you to do the following

essential functions:

• Track

and report on dealer and consignment inventory, including two (2) years

of consignment sales history by company, customer, ship-to, and part.

• Enter

stock quantities for dealer and consignment inventory.

• Set

up a consignment relationship with a specified customer.

• See

what part quantities are on consignment when creating an order.

How It Works

You set up a “Consignment Vendor” for each customer’s

Ship-To that will receive consignment inventory. There must be a unique

consignment vendor for each Ship-To as this is part of the tracking and

reporting mechanism. Then, in order to ship parts to the customer, you

use a negative purchase order (a return). The return reduces the part’s

quantity on hand by the quantity of the consignment parts. When you receive

the purchase order, Vision updates the consignment inventory record for

the part. During End Of Day processing, the system vouchers the negative

purchase order at zero dollars, using a Consignment Inventory general

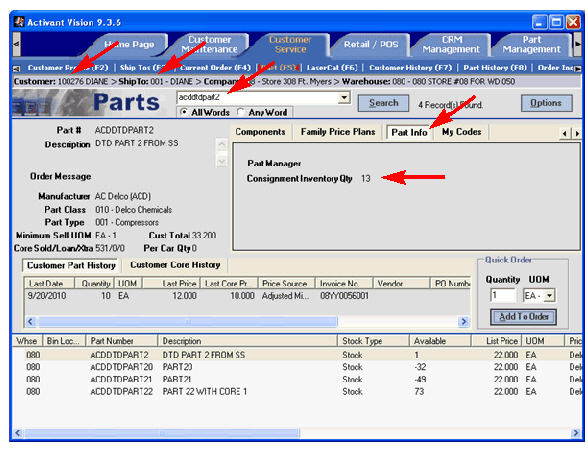

ledger account. The quantity of consigned parts is displayed on the Part

(F5) screen under the Part Info subtab (under both Customer Service and

Retail/POS).

Note: EOD

automatically knows to voucher the negative purchase order at zero dollars

because the PO is for a consignment vendor.

Periodically, you take a physical count of the

consignment inventory, using a Consignment Count Sheet. Based upon the

physical count, the consignment inventory is replenished through the “Consignment

Vendor” by means of another return purchase order and the parts that were

sold are billed via an order.

Back to Top.

System Configuration

Follow these procedures to configure your

system for handling consignment inventory. These procedures help you set

up your GL Account rules and variance codes for handling the negative

purchase orders you use to put parts on consignment with a specific customer.

• Set Up New

GL Account Rules

• Set Up a Consignment

Variance Code

• Set the

Dealer Consignment Inventory Variance Code

Back to Top.

Set Up New GL Account

Rules

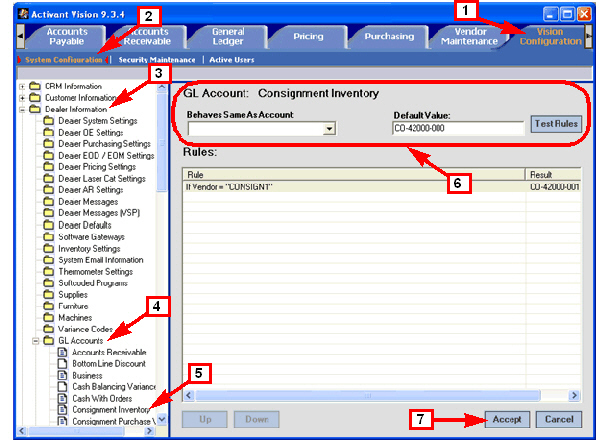

1 Click

Vision Configuration.

2 Click

System Configuration.

3 Open

the Dealer Information folder.

4 Open

the GL Accounts folder.

5 Click

Consignment Inventory.

6 Set

up the GL Account rules as needed for your business.

7 Click

Accept.

Back to System Configuration.

Back to Top. |

|

Set Up a Consignment

Variance Code

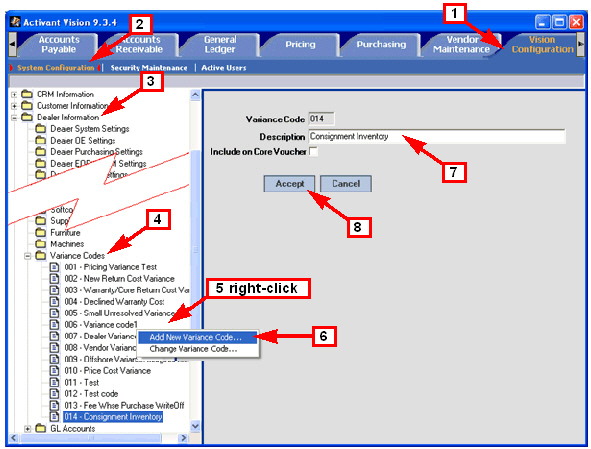

1 Click

Vision Configuration.

2 Click

System Configuration.

3 Open

the Dealer Information folder.

4 Open

the Variance Codes folder.

Note: If

you find that the Consignment Inventory variance code already

exists, you can skip the rest of this procedure. Otherwise, continue.

5 Right-click

anywhere in the tree list of variance codes.

6 Select

Add New Variance Code from the popup menu.

7 Type

the description as “Consignment Inventory.”

8 Click

Accept.

Back to System Configuration.

Back to Top.

|

|

Set the Dealer

Consignment Inventory Variance Code

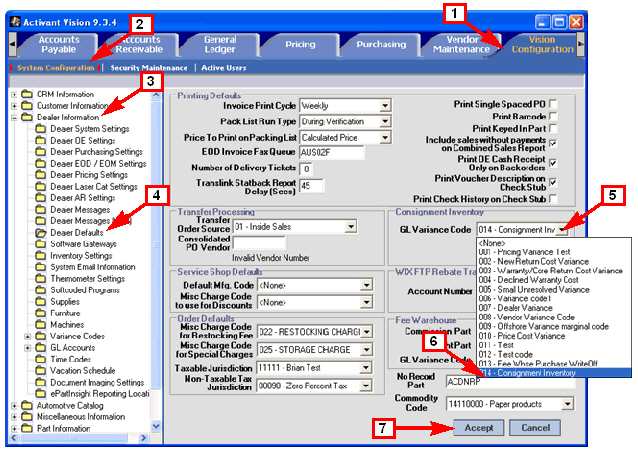

1 Click

Vision Configuration.

2 Click

System Configuration.

3 Open

the Dealer Information folder.

4 Open

the Dealer Defaults folder.

5 Click

the down-arrow for the list of GL Variance Codes.

6 Select

Consignment Inventory from the drop-down list.

7 Click

Accept.

Back to System Configuration.

Back to Top. |

|

Customer Configuration

Follow these procedures to configure a customer

to receive consignment inventory through a consignment vendor.

Procedure |

Comments |

Create a Consignment Vendor |

A consignment vendor is a fictitious

vendor you use for shipping and tracking inventory on consignment

with a specific customer. |

Assign the Consignment Vendor to the Customer |

The consignment vendor must be

associated with only one customer. In fact, the system displays

an error if you try to assign a consignment vendor to more than

one customer or customer ship-to. |

Back to Top.

Create a Consignment

Vendor

A consignment vendor

is a fictitious vendor you use for shipping and tracking inventory

on consignment with a specific customer.

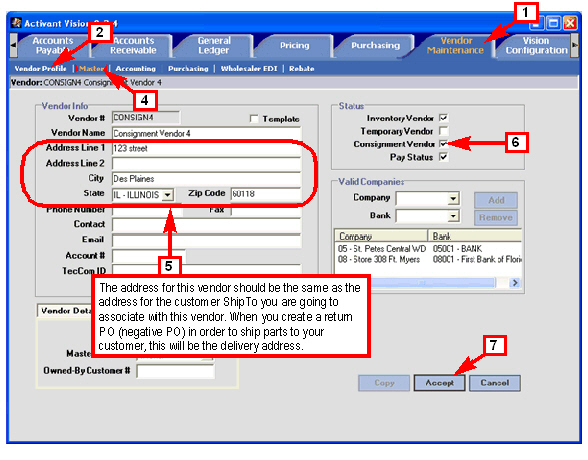

1 Click

Vendor Maintenance.

2 Click

Vendor Profile.

3 Create

a new vendor. (Not shown at right.)

See Create a Vendor from Scratch in

the online help for detailed instructions.

4 Click

Master.

5 Input

the same address for this vendor as for the customer ShipTo you

want to use.

Note: You

will later associate this vendor with a single customer ShipTo.

The address for this vendor should be the same as that ShipTo.

This will be the delivery address for parts shipped to the customer

via a return purchase order.

This vendor will be used only for handling consignment inventory

for that specific customer. You should give this vendor a name

that makes it easy to remember which customer it is used for.

6 Set

the vendor’s status to Consignment Vendor.

Note: You

must put a check mark in this box in order for the vendor to show

up in the Consignment Vendor list on the Customer Maintenance

—> ShipTo Preferences screen.

7 Click

Accept.

Back to Customer

Configuration.

Back to Top. |

Note: This

vendor should only be used for consignment inventory. Writing

a purchase order for a consignment vendor reduces consignment

inventory and creates a voucher at End of Day. |

Assign the Consignment

Vendor to the Customer

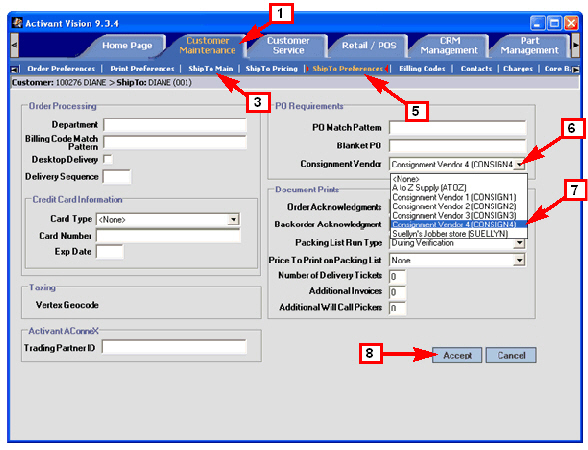

1 Click

Customer Maintenance.

2 Select

a customer. (Not shown at right.)

See Select a Customer in the online

help for detailed instructions.

3 Click

ShipTo Main.

4 Select

a ship to location from the list view.

(Not shown at right.)

This is the ship to you want to associate with the consignment

vendor you created earlier.

5 Click

ShipTo Preferences.

6 Open

the Consignment Vendor drop-down list.

7 Select

the consignment vendor to associate with this ShipTo location.

8 Click

Accept.

Note: Trying

to assign a consignment vendor to more than one ship-to produces

an error.

Back to Customer Configuration.

Back to Top.

|

|

Consignment/Dealer

Inventory Inquiry and Maintenance

• Consignment/Dealer

Inv

• Consignment/Dealer

Inv Search Filters

Consignment/Dealer

Inv

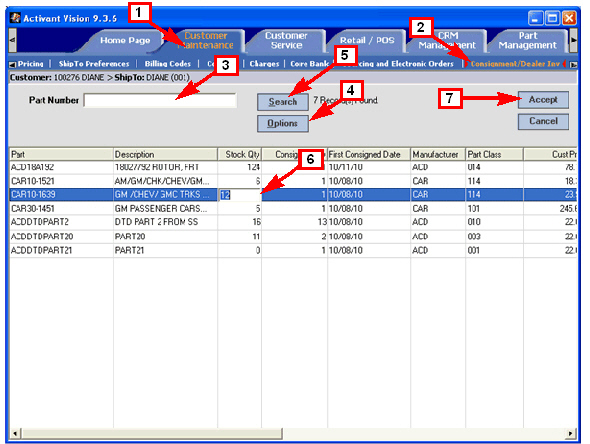

1 Click

Customer Maintenance.

2 Click

Consignment/Dealer Inv.

3 Type

in a part number, or leave it blank.

4 Optionally,

click Options and enter search filters. (See Consignment/Dealer Inv Search Filters for details.)

5 Click

Search.

6 Make

changes to the Stock Qty amounts, if necessary.

This value is used as a guideline

(or target) for how many units of a particular part you want to

keep on consignment.

7 Click

Accept to save your changes.

Back to Top.

|

|

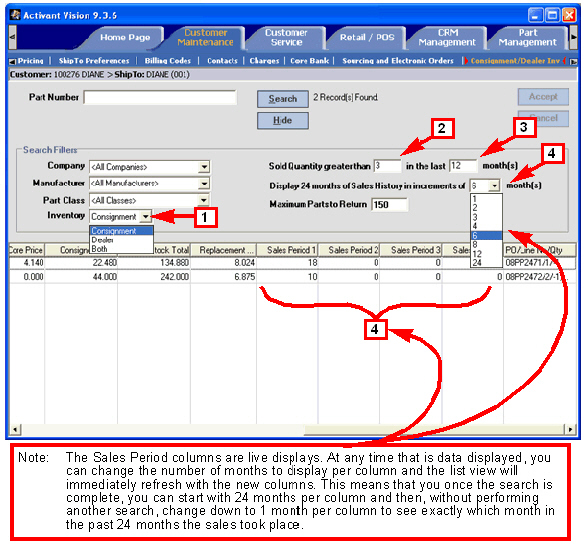

Consignment/Dealer

Inv Search Filters

In addition to

the usual filters of Company, Manufacturer, Part Class, and the

maximum number of parts to return, you can restrict your results

by the following filters:

1 Inventory

types:

• Consignment.

• Dealer.

• Both.

2 Quantity

sold.

1 to 99999.

3 Number

of Months to search for conforming sales quantity.

1 to 24.

4 Size

of Sales History increments to display.

1 / 2 / 3 / 4 / 6 / 8 / 12 / 24.

The system always displays

a total of 24 months of sales history. The number of columns the

system displays is 24 divided by the number of months in the increment.

For example, the display shown at right has four columns (24/6

= 4).

For an increment of 1, the

system displays 24 columns; for an increment of 8 there will be

three columns; for an increment of 24, there will be only one

column.

Note: The

lowest numbered sales periods always contain the most recent sales

months. For example, if the increments for sales history is set

to 24, then

• Sales

Period 1 = current sales month.

• Sales

Period 2 = previous sales month.

• Sales

Period 3 = sales three months ago.

Back to Consignment/Dealer Inventory Inquiry and Maintenance.

Back to Top. |

|

Starting the Consignment

Process

To begin sending your customers consignment parts,

do the following:

1. Create

a consignment vendor for your customer.

(See Create a Consignment

Vendor for details.)

2. Assign

the consignment vendor to your customer’s ShipTo.

(See Assign the

Consignment Vendor to the Customer for details.)

3. Create

a negative purchase order by selecting Return as the purchase order type.

Purchasing —> Current PO.

4. Receive

the purchase order.

When you receive the purchase order, the

system updates the following data visible on the Customer Maintenance —> Consignment/Dealer Inv

screen:

• Consigned Qty

• First Consigned

Date

• Consignment PO

• Consignment PO

QTY

5. During

EOD, voucher the purchase orders with zero dollars. The system uses the

Purchasing Returns and Consignment Inventory GL accounts for the distribution.

Note: If you need to

increase the consignment quantity, or you need to add different parts

to your customer’s consignment stock, you will need to create a new negative

purchase order.

Back to Top.

Tracking Inventory

and Charging for Parts Sold

This section covers consignment inventory counts,

using orders to charge the customer for parts sold, and using reports

to track consignment inventory.

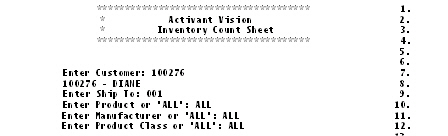

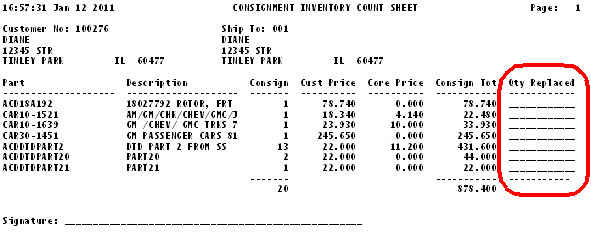

1 Print

an Inventory Count Sheet for the customer ShipTo.

Auto Menu 3.9.2, Inventory

Count Sheet.

OP Menu 8.9.2, Count Sheet.

The Inventory Count Sheet

asks for customer, ship-to, product, manufacturer, and product

class.

The printout looks similar

to the example below right. |

|

2 Replenish

the consignment stock.

When you replenish the consignment

stock, note the quantity replaced on the consignment inventory

count sheet in the area circled in red shown at right.

Note: Do

not create another negative purchase order to replenish an established

consignment stocking level. Only create a negative purchase order

when increasing the consignment stocking level or when adding

new parts to consignment.

|

|

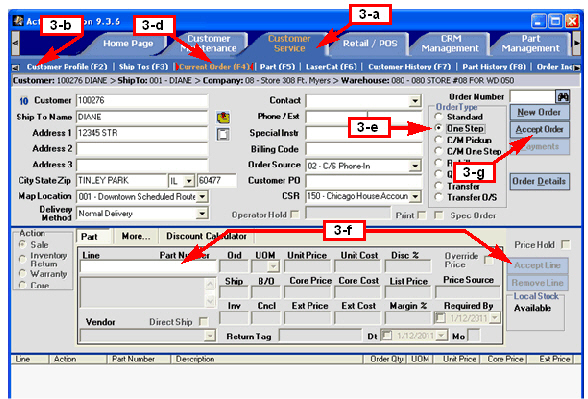

3 Create

an order for the consignment inventory sold at the customer’s

site, based on the inventory count results.

a Click

Customer Service.

b Click

Customer Profile.

c Select

the desired customer.

(Not shown at right.)

d Click

Current Order.

e Set

the Order Type to One Step.

One Step orders relieves inventory but does not print a pick ticket.

f Enter

the parts, accepting each line.

g Click

Accept.

The order will charge the customer

for the parts sold.

|

|

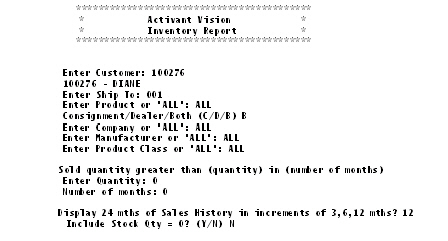

4 Generate

a the Consignment/Dealer Inventory report.

Auto Menu 3.9.1, Inventory

Report.

OP Menu 8.9.1, Inventory

Report.

The report prompts are shown

at right.

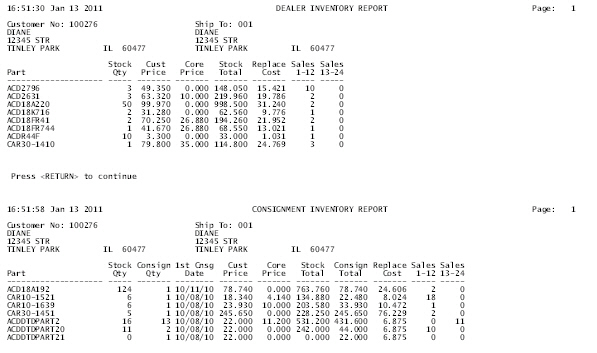

An example of the report

sent to the screen is shown below right.

|

|

Dealer and Consignment

Inventory Reports are both generated. They should look similar

to the example at right.

Back to Top. |

|

Ending the Consignment

Process

To end consignment with a customer, do the following:

1. Perform

an inventory count and remove any parts remaining at the at the customer’s

ship-to.

2. Create

an order to charge the customer for any parts they sold.

3. Create

one or more purchase orders for the consignment vendor.

These purchase orders should reverse all

negative purchase orders created during the consignment.

4. During

EOD, voucher the purchase orders with zero dollars. The system uses the

Purchasing Returns and Consignment Inventory GL accounts for the distribution.

Back to Top.

Part (F5) Screen

Customer Service

—> Part (F5)

Retail / POS —> Part (F5)

On the Part (F5) screen, if you

have a Customer and a ShipTo defined and that ShipTo is associated

with a consignment vendor, when you look up a part that is on

consignment, you can look at the Part Info subtab to see how many

units of that part the customer is stocking on consignment.

Back to Top. |

|