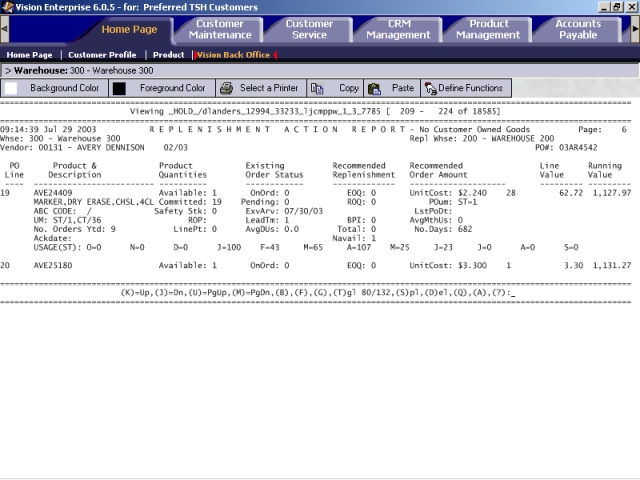

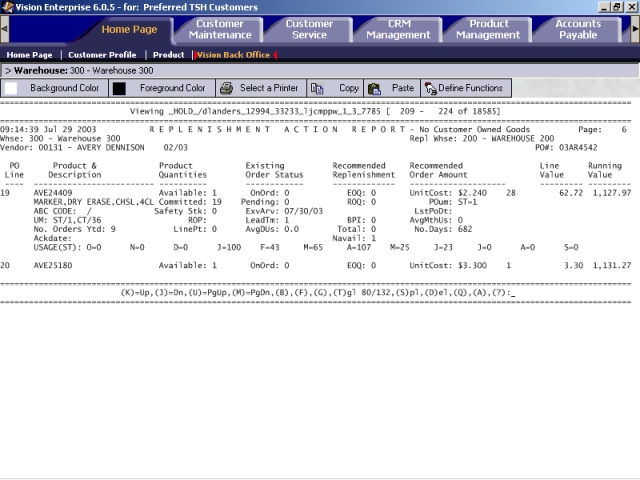

During End-of-Day processing and during on-demand stock replenishment, the system identifies products in need of replenishment. It creates pending purchase orders (POs) for those products and places the POs on the Replenishment Action Report. On this report, the system has assigned a PO number and pulled all of the necessary purchase order information together for you.

You can analyze the Replenishment Action Report and decide which POs to edit, activate, and send to the vendor. For information on editing and activating POs, refer to Overview of Purchase Order Entry/Maintenance.

Note: You are not committed to order any product that appears on the Replenishment Action Report. It is merely a record of pending POs that you may or may not choose to activate (or maintain) to turn a PO into a buy.

The Replenishment Action Report is sorted by vendor, and each PO directed to a vendor is given its own PO number. Special items and non-stock items have their own section on the report, as well as stock cost override items. A recommended order amount is included for each item. Each pending purchase order is divided into five sections: (1) Items Below Safety Stock, (2) Items Below Reorder Point, (3) Items Below Line Point, (4) Items Above Line Point B/4 Price Increase, and (5) Special/Non-Stock Items. These sections or groups of products are displayed on each pending purchase order in the order of urgency to buy.

Two versions of the Replenishment Action Report are available:

Replenishment Action Report— No Customer Owned: This version contains items that you sell to all customers.

Replenishment Action Report— Customer Owned: This version contains items your customers have already purchased from a source other than your company and you are keeping and tracking the inventory for the item at your warehouse. Customer-specific preprinted forms is an example of a typical “customer-owned” item. This report can be printed by your purchasing personnel and given to your customer, so that your customer knows when to reorder his or her preprinted forms.

The Replenishment Action Report is divided into the following sections to help you determine the order of urgency to buy.

Items Below Safety Stock: The products included in this section of the report are critically in need of purchasing. You do not want to wait for the quantity to reach the free freight point offered by the vendor. (The dollar amount necessary per PO to receive the free freight is printed in the Free Freight Amt field at the end of the purchase order, in the total area.) These products must be purchased right away.

Items Below Reorder Point: The products included in this section of the report are at a quantity that make now the ideal time to order. However, you may wish to leave the PO inactive and wait for the quantity to reach the free freight quantity offered by the vendor. (The dollar amount necessary per PO to receive the free freight is printed in the Free Freight Amt field at the end of the purchase order, in the total area.)

Items Below Line Point: A product is included in this section of the report when its quantity falls below the outside limit for including the item on a purchase order for this vendor.

Items Above Line Point B/4 Price Increase: This purpose of this area of the report is to alert you about products that you may wish to “stock up on” prior to an upcoming price increase from the vendor.

Special/Non-Stock Items: This area of the report lists any products that are not carried in stock but are to be purchased for specific customer order lines.

The following columns and fields are displayed on the Replenishment Action Report:

Whse: This is the warehouse associated with this purchase order.

Repl Whse: This is the replenishment warehouse assigned to the warehouse associated with this purchase order. The Warehouse maintenance on the System Configuration screen of the Vision Configuration tab is where you specify a replenishment warehouse for a warehouse. For more information, refer to Select a warehouse's supporting warehouses.

Vendor: This is the vendor associated with this purchase order.

PO#: This is the company number plus the purchase order number. The first two digits represent the company number.

PO Line: This is the line number on the Replenishment Action Report for a product.

Product & Description: This column contains the product number and description. In addition, this column contains the following fields:

ABC Code: An ABC code indicates how fast a stock or temporary product moves in a warehouse. For example, if a product has a high turnover rate, then it is a fast mover. The ABC codes can be used to determine how much of stock product to buy and when to order to assure the right turnover.

You can use an ABC model to rank products based on average monthly usage during a rolling 12-month period in one or more warehouses. The system then assigns ABC codes to products based on those rankings. The ABC Model screen of the Purchasing tab is where you set up an ABC model. For more information, refer to Set up a new ABC model.

The System Configuration screen on the Vision Configuration tab is where you select an ABC model for a warehouse. For more information, refer to Specify ABC classification settings for a warehouse.

To learn how the system updates the ABC code and the other replenishment-related factors, refer to Overview of inventory replenishment.

UM: This indicates the units of measure for the product; the quantity multiple for each unit of measure is included.

No. Orders Ytd: This is the year-to-date number of orders that include this product.

Ackdate: This is the

Product Quantities: This column contains the following fields:

Available: This is the available quantity of the product. It is calculated by using the following equation:

Available Quantity = On-Hand Quantity - Backorder Quantity - In-Pick Quantity

Committed: This is the quantity of the product committed to customer orders. It is calculated by using the following equation:

Committed Quantity = Backorder Quantity - In-Pick Quantity

Safety Stk: This is the safety allowance that takes care of reasonable variations in usage or lead time from the averages anticipated. It is the minimum amount of stock necessary to fill orders based on average daily usage and the manufacturer lead time.

You can use reorder point (ROP) models to specify settings for calculation of the safety stock quantity. For more information, refer to Set up or modify reorder point calculations for an ROP model.

To learn how the system calculates and updates the safety stock quantity and other replenishment-related factors, refer to Overview of inventory replenishment.

ROP: This is the reorder point quantity of the product. It is the on-hand quantity that triggers the system to automatically include the product on a pending purchase order for the primary vendor or on a replenishment transfer order.

The system's built-in calculation for reorder point takes into consideration that enough merchandise (usage) must be ordered to fill customer orders during the time required to get more stock (lead time); at the same time, a safety allowance needs to be included to ensure that minimum stock requirements are met.

You can use reorder point (ROP) models to specify settings for calculation of the ROP. For more information, refer to Set up or modify reorder point calculations for an ROP model.

To learn how the system calculates and updates the ROP and other replenishment-related factors, refer to Overview of inventory replenishment.

LinePt: The linepoint sets the outside (maximum) quantity limit for including the product on a pending purchase order for the primary vendor.

You can use reorder point (ROP) models to specify settings for calculation of the linepoint. For more information, refer to Set up or modify reorder point calculations for an ROP model.

To learn how the system calculates and updates the linepoint and other replenishment-related factors, refer to Overview of inventory replenishment.

Existing Order Status: This column contains the following fields:

OnOrd: This is the quantity on order— the total quantity for this product on purchase orders that have been activated. It is shown in the product's lowest unit of measure.

Pending: This is the quantity that represents the total quantity for this product on all POs that have not been activated. It is shown in the product's lowest unit of measure.

ExvArv: This is the expected arrival date for this product.

LeadTm: This is the manufacturer's average lead time for the product— the average number of days between purchase order activation and receiving dates for a stock product (excluding drop shipments).

AvgDUs: This is the average daily usage for this product. A product's average daily usage is calculated by dividing the average monthly usage by 22.

Recommended Replenishment: This column contains the following fields:

EOQ: This is the economic order quantity of the product. EOQ is one of the factors used in determining the reorder quantity. You can use reorder point (ROP) models to specify settings for calculation of the EOQ. For more information, refer to Set up or modify reorder point calculations for an ROP model.

To learn how the system calculates and updates the EOQ and other replenishment-related factors, refer to Overview of inventory replenishment.

ROQ: ?

BPI: This is the before-price-increase quantity for a product. A quantity is included here only if the product is in the "Items Above Line Point B/4 Price Increase" section of the report.

Total: This is the quantity that has been added from the most recent PO generation. It is expressed in the product's lowest unit of measure.

Navail: This is what the new available quantity would be if all of the "on order" quantities on activated purchase orders and all of the pending purchase order quantities were received.

Recommended Order Amount: This quantity is listed to the right of the UnitCost field. The recommended order amount is the quantity of this product suggested to buy on this purchase order. This quantity is expressed in the purchase order unit of measure. This column contains the following fields:

UnitCost: This is the unit cost for the unit of measure indicated in the POum field.

POum: This is the PO unit of measure.

LstPoDt: This is the date of the last PO for this product.

AvgMnthUs: This is the average monthly usage of the product.

No.Days: Number of days.

Line Value: This is the PO cost of this line item.

Running Value: This is a running total of the PO costs for the PO.

USAGE(Unit of Measure): This row shows the average usage for each month of the year. An asterisk (*) displayed next to a monthly usage quantity indicates that the usage for the month has been manually overridden on the Usage screen of the Product Management tab; the override quantity is displayed instead of the actual quantity for that month. This manual entry usually represents an adjustment to a typical usage quantity so that the usage is not thrown off by unusual usage for a month. For more information, refer to Set up usage exceptions.

Order#: If the PO line item is linked to a customer order, the customer's order number is listed in this field.

Cust: If the PO line item is linked to a customer order, the customer's number and name is listed in this field.

Date: If the PO line item is linked to a customer order, the date of the order is listed in this field.

Qty: If the PO line item is linked to a customer order, the customer's order quantity is listed in this field.

UM: If the PO line item is linked to a customer order, the unit of measure for the product on the customer's order is displayed in this field.

Price: If the PO line item is linked to a customer order, the customer's price is displayed in this field.

Min PO $: This is the minimum purchase order dollar amount required by the vendor on the PO.

Min PO Wgt: This is the

Misc. Data: This is the

Current line review cycle: This is how many days you would need to wait before purchasing from the vendor so that you have a large enough purchase order (in dollar amount) to be eligible to have the freight charge waived. For example, a vendor might say that freight is free if you order $12,000 worth of products. For more information, refer to the Glossary definition of vendor review cycle.

To learn how the system calculates and updates the vendor review cycle and other replenishment-related factors, refer to Overview of inventory replenishment.

Total PO Amt: This is the total dollar amount for the products on this PO.

Free Freight Amt: This is the minimum PO dollar amount required by the vendor to be eligible to have the freight charge waived.

Difference: This dollar amount is the difference between the total PO dollar amount and the free freight amount.

Multiplier: This is the

Following is a sample of the Replenishment Action Report displayed from the spooler hold file: